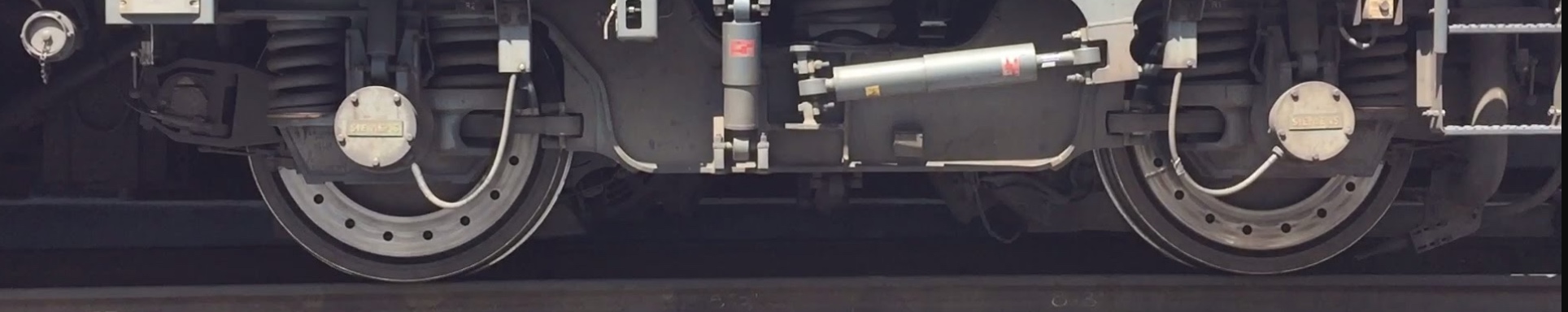

Wires for Traction Motors

NewGen manufactures insulated wires suitable for the most commonly used three-phase AC induction traction motors and DC traction motors in electric locos.

Our technical team has vast experience in working with traction motor OEMs and repairers and possesses intimate knowledge of popular traction drives produced by ABB, Siemens, Alstom, Hitachi and GE, etc.

Your benefits:

- Superior ability to withstand cyclic TEAM (thermal, electrical, ambient and mechanical) stresses

- Voltage endurance requirement at high frequency

- Operational reliability under harsh environmental conditions of vibration, shock, humidity, ambient temperature etc.

- Suitable for winding methods for high space factor

NewGen product offerings

-

Kapton ® Polyimide Wire

Kapton ® polyimide film with FEP adhesive wrapped to desired overlap to achieve required insulation thickness The film is bonded to copper which is cleaned for better adhesion, by high frequency induction heating combined by radiant heating to obtain a void free and uniform insulation that can withstand high operating temperature for continuous duty application. The film covered wire meets all requirements of a traction duty motor, harsh environment conditions and mechanical stresses like vibration

-

Corona resistant Kapton ® polyimide wire

Polyimide film with corona/partial discharge resistant property for AC traction motors. Additionally the film has better thermal conducting properties compared to standard polyimide film. Enhanced thermal transfer properties makes it ideally suited for variable frequency drives

-

Class 240 Polyimide enameled flat wires

Polyimide in liquid form is coated on to copper wire, produces a very smooth and highly flexible coating to a fine coating thickness of 100 to 120 microns, coated film can withstand temperatures up to 300 C, Thermal class of the coated wire is 240 C, wire is the prefered winding wire for traction generator, radiation resistant application such as motors for nuclear plants